Anchor Track™ & Components

Find your fit

Speed up your search for fall protection

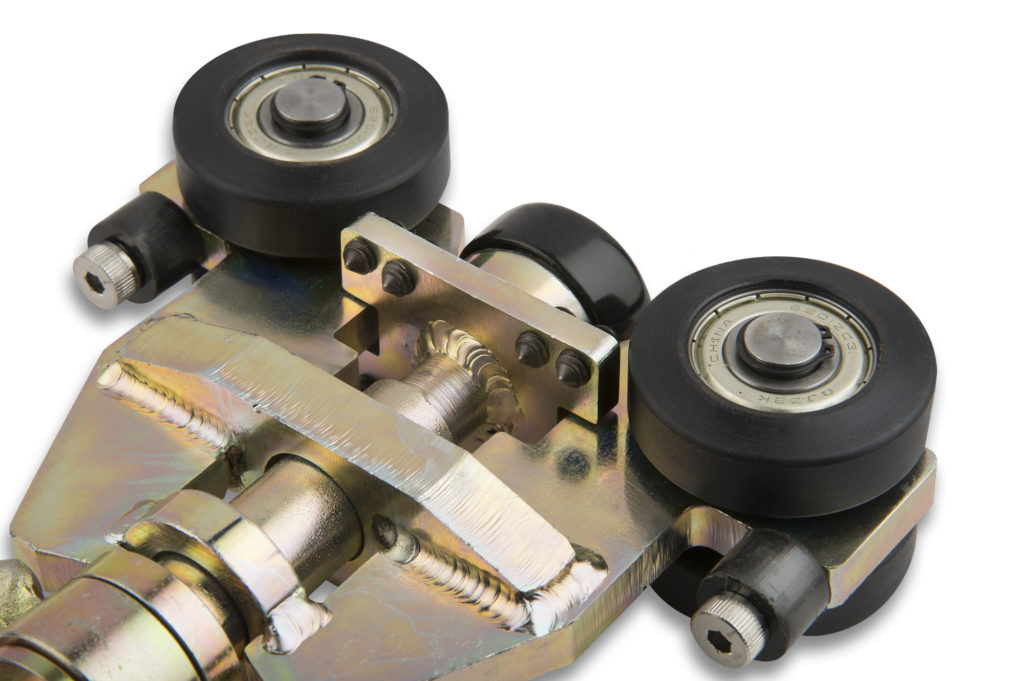

Permanent fall protection systems are integral for workers who are regularly exposed to fall hazards. Anchor Track™ supports the crews you serve through overhead fall protection with an enclosed track. It serves as the anchorage component for fall protection systems, allowing workers to securely attach their full-body safety harnesses to the Anchor Trolley™.

Explore the systems and customization options below to learn how Rigid Lifelines® can help you satisfy your clients’ needs.

Find Your Perfect-Fit Product

Anchor Track™ Features

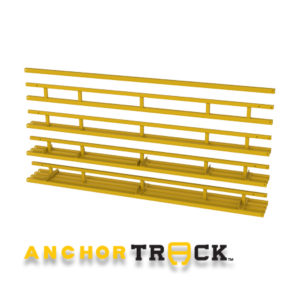

The Anchor Track™ fall protection system promotes safety and reduces the likelihood of a fall event. Key features include:

- An enclosed track design to shield the trolley from inclement weather, dirt, dust, and other environmental factors.

- Intermediate bumpers that can be installed to establish multiple work areas or limit trolley travel between factory-installed end stops.

- An internally tapered track that self-centers trolleys and end trucks for smooth, quiet, and ergonomic movement.

This product is engineered for both indoor and outdoor use, with finishes available to suit various environmental needs. It is also available in multiple track profiles and materials.

What Makes Anchor Track™ Fall Protection Systems Unique?

Depending on the needs of your clients’ facilities, we can offer our standard systems or develop custom solutions that meet the necessary specifications.

Various track options are available:

- Plain Track PT Series, including the Plain Single Track and the Stainless Steel Plain Single Track

- Trussed Track R Series, including the Trussed Single Track and Capped Trussed Single Track

- Dual Trussed Track DST Series, including the Trussed Dual Track

- Triple Trussed Track TST Series

- Quad Trussed Track QST Series

- Alu-Track® Series, including the Aluminum Single Track and Reinforced Aluminum Single Track

Tracks can be engineered to suit various lengths, heights, and workspace requirements. We can even accommodate curved track options for unique facility demands.

Our experts can also tailor the mounting solutions for Anchor Track™. Need a side- or ceiling-mounted track? We have you covered.

Anchor Track™ Compliance Requirements

All Anchor Track™ systems comply with OSHA 1910.66 (General Industry), OSHA 1926.502 (Construction), and relevant ANSI standards, such as ANSI Z359.11-2014 and ANSI A10.32-2012. Rigid Lifelines® stays current with code changes to ensure ongoing compliance.

Our track systems are engineered for a maximum weight of 310 pounds, including the worker, gear, and tools. We can provide custom systems to accommodate heavier loads.

At Rigid Lifelines®, we understand that safety is your clients’ top priority. Our products meet or exceed ANSI and OSHA requirements, so you can rest assured that our systems will provide reliable protection.

What Industries Can Benefit From the Rigid Lifelines® Anchor Track™?

The Anchor Track™ system can be used across many applications where overhead, rigid-rail fall protection is needed to support safety. Industries that can benefit from our tracks include:

Our heavy-duty track systems are engineered to reduce downtime and maintenance costs. After a fall incident, most Anchor Track™ systems require only a visual inspection and can return to service promptly.

Get Started With Anchor Track™ Today

Investing in the Anchor Track™ from Rigid Lifelines® can help your clients’ crews gain greater peace of mind, reduce fall risks, and maintain safer daily operations.

Our team can help you find perfect-fit products for your clients or get tailored solutions made specifically for their industries, facilities, and applications. Contact the experts at Rigid Lifelines® today to get started.