Single Post Suspension Fall Protection System Protects Industrial Waste Treatment Workers

Products used

Overview

Environmental Recovery Corporation (ERC) is a non-hazardous residual waste processing and treatment company based in Lancaster, Pennsylvania. With a 2.4-acre facility located in Lancaster, Pennsylvania, and an additional facility located in Baltimore, Maryland, ERC is the largest non-hazardous residual waste processor in the Mid-Atlantic.

Whether it’s through recycling, wastewater treatment, waste to energy processes, or landfill disposal, ERC treats each customer with an individualized approach that tailors to their unique mark on the sustainability spectrum. ERC’s customer base spans across multiple disciplines; including manufacturing, construction, oil, and environmental sectors.

The waste is brought from customer facilities to ERC in tanker trucks, where workers take samples of the waste. Each sample is tested onsite in ERC’s laboratory to determine its acceptance into the facility, and ultimately to designate its process method. The waste is then processed, treated, or recycled at their facility.

To collect the waste samples, workers must climb up the tanker trucks and open access manholes on the top of the tanks. ERC’s own fleet trucks are equipped with catwalks and guardrails, which help protect workers when taking the samples. However, Hannah Fritz, the Health and Safety Manager at ERC, explained that this solution isn’t always broad enough: “We receive waste through a lot of outside transportation companies, and they aren’t always designed with the same set-up. We needed a system that would work across varying truck styles.” During inclement weather, working on top of unprotected trucks could be especially dangerous, and ERC decided to take proactive steps to avoid any potential future accidents.

Solution

Environmental Recovery Corporation reached out to Ark Safety in Millersburg, Pennsylvania, to help them find a fall protection solution for their application. Employees at Ark Safety analyzed the application requirements and constraints, and they presented ERC with a range of different options.

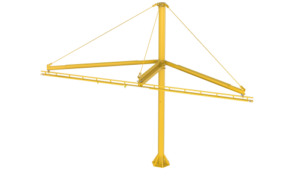

Together, ERC and Ark Safety determined that several Rigid Lifelines Single Post Suspension Fall Protection Systems offered the best solution for the application. The entire installation is composed of three individual vertical posts, each with a Rigid Lifelines Anchor Track™ monorail on each side, for a total of six tracks. Each track is 23 feet long with a trolley-hook height of 18 feet, six inches, providing sufficient clearance for many different types of tanker trucks.

Each individual system is mounted on a custom-engineered cylindrical foundation provided by Ark Safety. The foundations were made with concrete poured into four-foot diameter sonic tubes. Because the installation area is somewhat uneven, these custom foundations provide a level surface so each system could be installed identically. The foundations also keep the installation footprint to a minimum, which allows the tanker trucks to park as close to the fall protection systems as possible to maximize the limited space and allow up to six trucks to fit at one time.

Impact

Initially, Hannah said that there was some push-back from the workers when they first installed the system. ERC installed this system as a preventative measure, and many of the workers felt that, since they had been working for so long without any accidents, the fall arrest system wasn’t really necessary.

However, as the workers continued to use the system, they were able to work even more efficiently than before. The Anchor Trolley™ follows the workers overhead to improve safety without interfering with their work, so they can focus on the job instead of worrying about falling, especially on the outside fleet trucks that don’t have catwalks and guardrails. Hannah explained that, as the workers became accustomed to the system, “they quickly realized that it was more efficient and that they were safe. Now they wouldn’t think of working on top of the trucks without it.”

The fall protection system also provides peace of mind to the management at ERC by reducing the workers’ risk of serious injuries. But there was also a benefit that they hadn’t expected. Bill Specht from Ark Safety pointed out that ERC was taking a proactive approach to worker safety, and this proactive approach helps to improve ERC’s image to the companies it services: “Many companies invest in fall protection as a reaction to an incident. ERC installed the system before there was an incident, and it demonstrates to their customers that they emphasize safety and they invest strongly in providing their best services.”

Overall, the series of Rigid Lifelines Single Post Suspension Fall Protection Systems were the perfect fit for ERC’s needs. The six bays allow efficient sampling for the high volume of trucks they receive daily, it maximized the limited space available at ERC’s facility, and it protects the workers while working at height.

Click here to view a video of the system in use.