CUSTOMIZED FALL PROTECTION SYSTEM MAKES AIRPLANE STORAGE AND MAINTENANCE EASIER AND MORE EFFICIENT

Products used

Overview

A leading energy company has an aviation services facility that houses, maintains, and cleans company airplanes in Houston, TX. The aircraft in its fleet vary widely in terms of size and design, meaning the crews in charge of cleaning and maintenance have to account for varying wingspan lengths and heights off the ground as they move around on the planes’ exteriors.

However, the facility’s previous worker safety system—cables suspended from an “X” skeleton on the ceiling—only covered a fraction of available space in the hangar, which led either to unsafe maintenance conditions or to the planes having to be repositioned. With strict adherence to worker safety a part of the facility’s culture, management decided to upgrade to a fall protection system that would allow workers to access more of the hangar’s floor space safely and free personnel from having to reposition aircraft. They turned to Rigid Lifelines for a solution.

Solution

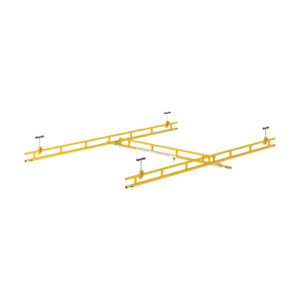

The energy company decided to install Rigid Lifelines Ceiling-Mounted Traveling Bridge Fall Protection Systems with dual trussed track bridges. The traveling bridges run between two steel trussed runways, providing 360 degrees of coverage to personnel as they work on the exterior of a plane.

This type of system provides improved safe access throughout the hangar because workers can walk nearly the length of the building, and the trolley follows directly overhead. Having dual trussed bridges in place permits two users to work on the same location on the plane and be able to pass each other freely. Additionally, having the bridge directly overhead minimizes swing fall, reducing injury risk to the worker as well as risk of damage to delicate components of the aircraft’s exterior in the event of a fall.

Impact

Rigid Lifelines Traveling Bridge Fall Protection Systems provided the flexibility necessary for maintenance crews to work on the various aircraft safely. Thanks to Rigid Lifelines, the hangar crews are now able to access 85 percent of the hangar floor, opening just about anywhere on the floor to airplane storage without fear of repositioning the aircraft or not having proper fall protection coverage.

The customized fall protection solution even accounted for elements of the hangar’s ceiling, such as large heaters and fans. The dealer who installed the system, Mark Pharr and Bill Landry of Pharr Better Solutions, said that the “extra care and attention that the Rigid Lifelines team gave to the customer’s order allowed us to be successful and allowed us to create a first-class installation.”