Whats New in the ANSI Z359 Fall Protection Code – Hazard Analysis and Fall Distance

December 10, 2010

The ANSI Z359 Fall Protection Code is continually getting better every year. These new standards are designed to make equipment selection easier and keep your workers safe. Here is just one of many new developments from ANSI that would be of interest to general industry and construction.

The only “user” standard in the entire series of ANSI Z359 equipment standards is Z359.2. The .2 standard is a new ANSI “user” standard that requires a hazard analysis and rescue plan be developed for every instance of fall protection. This is of significant importance in keeping your employees safe while wearing fall protection.

Common issues that potentially result in hospital visits after a fall event, even when using fall protection, are improper calculation of fall distance, failure to recognize injury hazards impacted during a fall, and swing fall injuries.

Improperly calculated fall distance can result in the user hitting a lower level. This can occur when either one of the following occurs:

- 18’-6″ of clearance from the attachment point is not provided when using the common 72″ long energy absorbing lanyard.

- Wire rope flex is not taken into account on horizontal wire rope systems. Flexible wire ropes will deflect downward significantly during a fall event. For example, a commonly available 100 foot long wire rope system may deflect 12’ or more during a fall event. This 12’ deflection added to the 18’-6″’ of clearance from the attachment point, requires about 30 feet of clearance when using a 72″ long energy absorbing lanyard.

Swing fall injuries can occur when the attachment point is not directly over the worker’s head. If the attachment point is not directly over the worker’s head, the fall can result in the worker being “swung” or “pulled” back into the work platform quite violently.

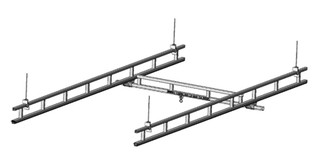

New developments have been made in equipment and fall protection systems that “engineer out” the dangers of fall distance and swing falls. Currently, what is widely recognized as the safest possible system to prevent injury to the worker is a rigid track “traveling bridge” used in conjunction with a self-retracting lanyard (SRL) that continually retracts, like a seat belt, to minimize fall distance. The traveling bridge is designed out of light-weight high strength steel or aluminum so it rolls freely along the runways. When the worker walks along the bridge the trolley follows the worker overhead without effort.

Traveling bridge with self-retracting lanyard (SRL) provides superior fall protection safety for all workers at height

Because the trolley always remains directly over top the worker’s head, this eliminates the swing fall effect. Any fall event will be straight down, resulting in no injury to the worker. This combination of the travelling bridge with the self-retracting lanyard provides the least amount of fall distance, eliminates swing falls, and provides the safest possible solution for the worker who needs to work at height.

To summarize, there have been many developments to keep workers safe, both in new regulations and in new equipment technology. To keep your workers protected, follow the new ANSI regulations and seek to minimize fall distance by using SRL’s and rigid attachment points. Where mobility is required, combine SRL’s with new rigid track monorails or traveling bridges to minimize fall distance and swing fall injuries to workers.

As the ANSI standards are continually evolving, please look for more “What’s New in the ANSI Z359 Fall Protection Code” blog entries in the future.

Thanks for reading!

As always- Stay safe, and I am here if you need me…..

Arnold Timothy Galpin, P.E.

Categories

Share this post

Let us help you

Contact us today to find the perfect product fit for your job