What Is Fall Protection and Why Is It Important in the Construction Industry?

March 27, 2023

The United States construction industry was responsible for more than one in five workplace fatalities in 2020. Over one-third of these incidents resulted from slips, trips, and falls. Nearly all of them involved falls to a lower level.

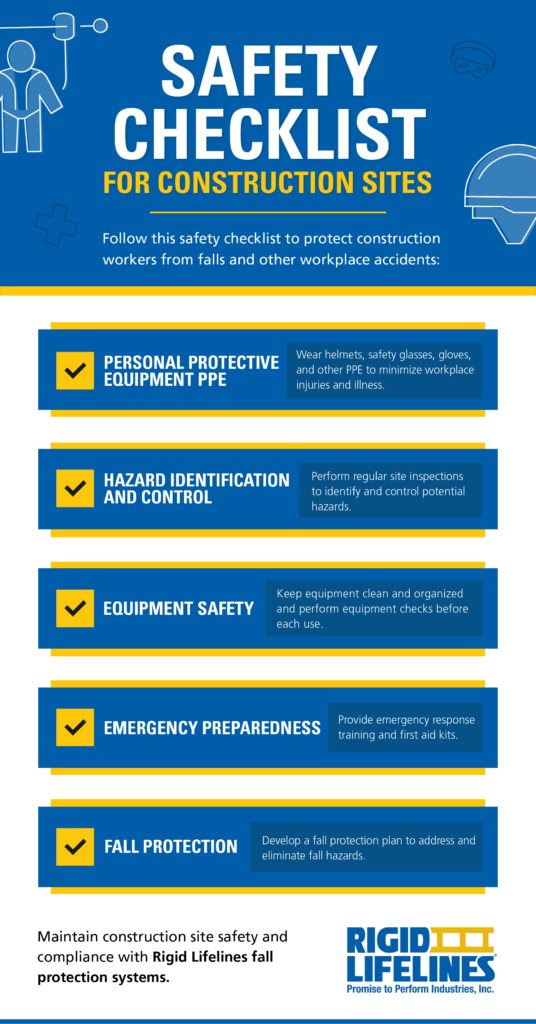

To protect construction workers from falls and other workplace accidents, the U.S. Occupational Safety and Health Administration (OSHA) enforces rigorous guidelines surrounding equipment and safety protocols. Fall protection is the practice of implementing preventive measures to protect personnel from falling and sustaining injuries.

You can take a few steps to ensure you’re following OSHA construction fall protection standards. In this article, we’ll cover some tips for safeguarding construction teams against dangerous falls.

7 Construction Safety Fall Protection Tips

Construction supervisors should set up the workplace to prevent people from falling off overhead platforms and other elevated work surfaces. According to OSHA fall protection construction standards, fall protection must be present at elevations of six feet. Supervisors must also implement fall protection over hazardous machinery and equipment, regardless of the fall distance.

To defend workers from potentially lethal falls, supervisors can:

- Guard floor holes and open-sided platforms with railings and covers.

- Provide safety nets, lines, and harnesses for those working on elevated surfaces.

- Provide a stairway or ladder for elevation breaks above 19 inches.

- Train employees about job hazards.

- Install fall protection systems.

Below are some essential tips to protect construction teams from falls and other injuries.

1. Focus on Training and Company Culture

In addition to witnessed violations, construction managers can receive OSHA citations for providing insufficient employee training. Giving your staff the proper equipment isn’t enough. To prevent falls and other incidents from occurring, they must know how to care for equipment, operate it safely, and understand its limitations.

A construction crew leader should provide training to any workers exposed to fall hazards — in other words, all of them. They should be educated on the proper use of every piece of equipment, from small stepladders to large excavators. The training program should be broad, covering numerous topics such as:

- Nature of the fall hazards associated with the construction site.

- Proper use, inspection, and maintenance of fall protection systems.

- Workers’ role in safety monitoring and upholding fall protection plan measures.

Additionally, those in charge should keep and maintain fall protection planning certification records for all workers. Retraining is also necessary for any changes made to training and safety protocols.

2. Perform Proper Inspections

According to OSHA construction fall protection standards, personal fall arrest systems should be inspected before each use for wear, defects, and damage. Damaged components should be removed from service immediately, and they should not be used again until inspected and deemed safe by a qualified individual.

Supervisors should perform regular site inspections. They should conduct a daily walk-through and examine all equipment, work surfaces, materials, and employee practices to ensure they are operating machinery properly and following safety protocols. Additionally, staff members should inspect each piece of equipment thoroughly before use, alerting a supervisor if they notice a potential risk.

A site safety supervisor should inspect the workplace for the following elements:

- Positioning and status of scaffolding, guard rails, and ladders

- Any new on-site fall hazards

- Conditions of personal fall arrest systems and fall restraints

- Employee safety badges and cards to ensure they have received proper safety training

3. Prioritize Cleanliness and Organization

A clean, organized workplace can go a long way in keeping staff members safe. Not only does a cluttered construction site reduce efficiency, but it also presents tripping and falling risks. Be sure to keep both ground and elevated surfaces clear of equipment, tools, and other potential hazards.

Surfaces should also be dry and free of mud, snow, ice, water, wet leaves, and other debris to prevent unwanted slips. On top of wearing personal protective equipment (PPE) when handling hazardous materials, workers should clean up any spills right after they occur. This can reduce the risk of slipping on liquid chemicals and falling.

Furthermore, remember to clean eye and face protection to keep them in good condition. Proper visibility can help mitigate falls and other incidents, as employees are more aware of their surroundings.

Construction members should inspect all eye and face protection carefully before use, ensuring they’re free of chips, cracks, smudges, and other defects. Any eye or face protection showing damage should be replaced immediately.

4. Follow Safety Protocols and Requirements

To prevent falls and other injuries on construction sites, all members should uphold basic safety protocols such as:

- Wearing PPE.

- Reading and following signage.

- Keeping the site clean and organized.

- Avoiding misuse of tools and equipment.

- Performing equipment checks before use.

- Reporting issues to supervisors immediately.

5. Develop a Thorough Fall Protection Plan

A fall protection plan outlines and addresses any fall hazards associated with construction sites. It should cover measures and practices to prevent these risks, as well as proper steps to take when they do occur.

While these plans should be unique to each construction site, OSHA offers a fall protection plan template with recommended checklists. You can map out identified fall hazards and corrective actions to prevent falls. Fall hazards to address in your plan might include the following:

- Stairways

- Handrails

- Roofs

- Ladders

- Scaffolding

Once you have a comprehensive fall protection plan in place, it’s important to go over this plan with all members of your construction crew. That way, everyone knows the correct protocols for mitigating and handling falls.

6. Plan and Adapt to Site Conditions

Your construction site conditions largely influence safety. When walking around the site, look for hazards that could cause slips, trips, or falls, then plan and adjust as necessary. Adjusting to your site conditions might involve:

- Putting down rock over muddy areas.

- Filling and covering holes.

- Identifying changes in elevation from grade to slab.

7. Devote Special Consideration to Scaffolding

While it’s important to check every piece of equipment for fall hazards, scaffolding is an especially crucial consideration. Scaffold injuries and fatalities often occur from:

- Plank or support collapses.

- Slipping.

- Lack of fall protection.

- Being struck by a falling object.

Complying with OSHA scaffolding standards can reduce these incidents. Before every work shift, scaffolds should be thoroughly inspected by trained, qualified professionals, addressing any hazards that could affect their structural integrity.

Find Fall Protection Equipment for Construction at Rigid Lifelines

At Rigid Lifelines, we specialize in permanent fall protection systems for construction sites and other industries. All of our fall protection Anchor Track™ Systems comply with OSHA and the American National Standards Institute (ANSI). Our solutions adhere to these regulations to reduce falls and other workplace hazards, enhancing safety standards for your personnel.

If you need assistance in finding the right fall protection solution for your needs, please contact our team at any time.

Categories

Share this post

Let us help you

Contact us today to find the perfect product fit for your job