Are Guardrails Considered Fall Protection?

August 3, 2023

Construction projects frequently require workers to perform tasks at heights. Because of the inherent dangers, the Occupational Health and Safety Administration (OSHA) has instituted stringent safety regulations to safeguard against falls that can lead to severe injuries and accidental deaths.

Generally, OSHA permits companies to provide what it refers to as “conventional fall protection” solutions for their workforce. These entail implementing personal fall arrest systems, safety net systems, or guardrail systems.

Components of a Guardrail

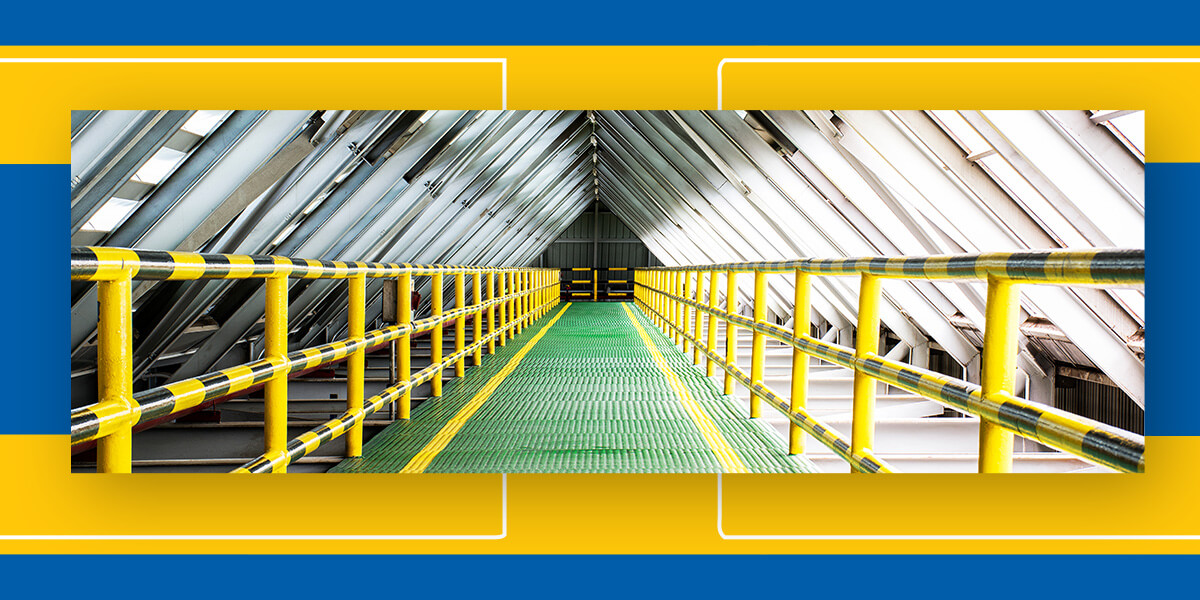

According to OSHA 29 CFR 1926.502(b), a guardrail system is a barrier constructed to keep workers from falling to lower levels. Specifically, a guardrail is a stationary structure that prevents individuals from stepping over the edge of a walking surface.

A guardrail system contains several components:

- Top rails

- Mid-rails

- Vertical posts

Users can add additional layers of materials, such as screens, mesh, and balusters, to enhance the guardrail system’s protective capabilities.

OSHA Guardrail Provisions

OSHA requires that companies utilizing guardrails for fall protection adhere to numerous provisions, including:

1. Top Rail Height

All top rails must be 42 inches above the walking-working level. OSHA allows a variance of plus or minus 3 inches. If workers are using stilts, companies must raise the top rails to equal their height.

2. Mid-Rail Specifications

The placement of mid-rails must occur halfway between the top of the guardrail and the walking or working level unless there is a wall or parapet at least 21 inches high. Any screens or mesh should extend from the top of the rail to the walking-working surface and cover the entire opening between the rail posts. When using these accessories, their placement must be no more than 19 inches apart.

3. Rail Strength

Guardrails need to be strong enough to prevent workers from falling to the surface below. Any point along the top rail must be able to support a minimum force of 200 pounds when applied within 2 inches of the top edge in a downward or outward direction. The mid-rails and supporting materials like mesh and screens must be able to accommodate at least 150 pounds of applied force at all points.

4. Rail Surfaces

Rough surfaces pose many potential hazards to workers. All rails in a guardrail system must contain smooth surfaces to reduce the risk of cuts or clothing snagging on sharp edges and causing a fall. Also, the ends of the top rails and mid-rails cannot hang over the end posts.

5. Hole Placement

Some elevated construction sites require the use of holes that serve as access points for workers and equipment. The guardrail system opening for these installations must include a self-closing gate that opens away from the hole. This gate must have a compatible top rail and mid-rail or an equivalent structure.

Fall Protection Options — Different Types of Systems

Guardrails represent one type of fall protection system used at construction sites. Safety nets and personal fall arrest systems are two other OSHA-regulated methods for safeguarding workers.

A safety net system is an example of passive fall protection, meaning that the device doesn’t move, adapt, or alter. Its purpose is to catch workers before they strike the ground after a fall. The netting must be installed as close as practicable under walking or working surfaces but never more than 30 feet below them. It must also have sufficient clearance to prevent the force of falling workers from pushing it to the surface.

Companies must conduct drop-testing to ensure the nets function correctly and safely. The openings in the netting’s mesh cannot exceed 36 square inches or be longer than 6 inches on any side. The mesh crossings must be secured to prevent enlarging of the openings.

A personal fall arrest system is designed to stop workers who fall from a high level. It consists of a body harness worn by the worker that is connected to an anchorage device via mechanisms like Dee-rings, snap hooks, or lanyards. The rigging of these systems must prevent the working from free-falling more than 6 feet or contacting any lower level. It must bring the worker to a complete stop while limiting the deceleration distance to 3.5 feet.

Fall Protection vs. Fall Prevention

While fall protection and fall prevention are often used interchangeably, the concepts are different in several ways. Fall prevention refers to any system or process intended to limit or eliminate the risk of an accidental fall. Examples include using a lanyard to keep a worker from reaching an unprotected edge, or installing a barrier to stop a fall.

Fall protection encompasses two subcategories — fall restraint and fall arrest. According to OSHA, the term refers to the specific implementation of equipment, devices, or systems intended to keep workers from falling or mitigating the effects of a fall.

Our Fall Protection Systems

Rigid Lifelines® provides advanced permanent and mobile fall protection solutions designed to keep workers safer at heights. Our systems meet all applicable OSHA and American National Standards Institute (ANSI) fall protection codes, ensuring regulatory compliance and giving you more peace of mind.

Our revolutionary Anchor Track™ Systems are our most popular fall protection product. They feature a rigid rail-enclosed track that won’t deflect during a fall event, reducing the distance a worker falls before stopping. They also require minimal maintenance — you’ll only need to conduct a visual inspection instead of a complete component recertification or replacement.

Learn more about your fall protection options so you can make an informed purchasing decision for your business by contacting Rigid Lifelines® today.

Categories

Share this post

Let us help you

Contact us today to find the perfect product fit for your job