Fall Protection for Tanker Trucks, Loading Docks, Flatbed Trucks, and Railcars

August 4, 2016

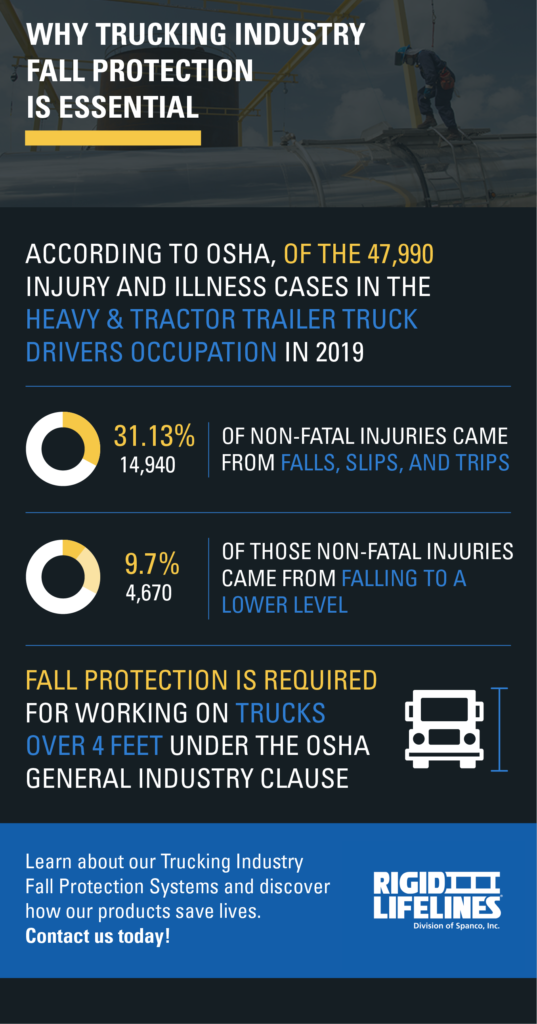

The transportation industry often requires workers to climb atop tanker trucks, flatbeds, and even open or closed trailers on a regular basis. It’s often unknown that more people die falling from 20 feet or less than from much higher heights. There are many other risks to transportation professionals, but the daily tasks of servicing large vehicles and loading and unloading trucks can present serious and life-threatening fall hazards. The transportation industry is often overlooked in regard to fall protection, and yet many workers suffer severe injuries and even death each year falling from tanker and flatbed trucks, among other types of transportation systems.

Even so, there are only some OSHA regulations that apply to fall protection for drivers and other workers climbing atop trucks and trailers to strap and secure loads. For years, OSHA did not implement clear regulations in regard to the transportation industry. In 2004, several regulations were implemented to protect workers, however, one specific regulation was too broad, as it encompassed a wide-range of applications. This particular regulation applied to unprotected sides and edges (in general) and falls under OSHA 1926.501(b)(1). It states:

Each employee on a walking/working surface (horizontal and vertical surface) with an unprotected side or edge which is 6 feet (1.8 m) or more above a lower level shall be protected from falling by the use of guardrail systems, safety net systems, or personal fall arrest systems.

This regulation was written and intended to encompass ANY working or walking surface that workers might be exposed to while conducting their job. It was most definitely intended to include flatbed trucks and trailers, particularly because workers must use these surfaces to conduct their daily tasks. But, it’s caused some confusion in the transportation industry in regard to fall protection.

OSHA has since updated their interpretation from 2004 to omit trailers and vehicles from that regulation. While there are currently no OSHA standards designed specifically for the trucking industry, OSHA now uses the General Industry clause (OSHA 29 CFR 1910.23(c) — (General Industry) as it relates to transportation:

Every open-sided floor or platform four feet above an adjacent floor or ground level shall be guarded by a standard railing on all open sides except where there is entrance to a ramp, stairway or fixed ladder”

In other words, when loading and unloading trailers within four feet from the next surface at a general industry site, fall protection is needed.

If you’re looking to protect your transportation workers but you’re having trouble deciding which type of system meets your specific cost and application requirements, there are a wide-variety of solutions available today. These systems are all designed to protect workers from hazardous scenarios that occur on a regular basis in the transportation industry. While there are many solutions available to prevent falls, there are only two main fall arrest categories designed for the transportation industry and trucking facilities: permanent (rigid) lifelines and portable lifeline or guardrail systems.

Permanent Fall Protection Systems

Although there is a need for portable systems in the transportation industry, for most work environments permanent systems are more efficient and cost effective because they only need to be installed once. Permanent fall protection systems are essential for workers who are regularly exposed to heights. Overhead rigid track systems are the most common permanent system for trucking facilities and transportation services, particularly in a facility where their vehicles must drive in and out of the same loading lane each day. In this case, an overhead rigid track system is installed over the loading lanes, allowing workers to move back and forth over the tops or sides, with their self retracting lifelines attached to the overhead track.

Permanent systems like these are often installed outdoors in the form of a freestanding rigid track or other type of horizontal system. They are often installed for the transportation industry using a T-shaped or L-shaped frame. But, they can also be installed indoors for transportation bays where workers must climb atop flatbed trucks to load and unload equipment and materials. In these situations, the rigid track can be ceiling or wall-mounted in an indoor facility.

Portable Solutions

Portable rigid track systems are best used in facilities and applications where there is no fixed work station. This mostly applies to loading docks, where workers must move from truck to truck to service vehicles. These types of portable fall arrest systems must be moved and assembled next to or on top of the vehicle itself.

Over the years, we have developed several other types of portable systems that are suitable for the trucking industry, including systems where the rigid track that secures the lifeline is mounted on an Inverted-U Frame. Additionally, portable ladder lifeline systems (with OSHA-compliant cages) for working on a tanker truck or around an open hatch can also be useful for the right application, but tend to provide less protection than a rigid track system.

Categories

Share this post

Let us help you

Contact us today to find the perfect product fit for your job